Maximum Playing Pleasure.

Zero Tropical Wood.

Maximum Playing Pleasure.

Zero Tropical Wood.

Domestic Wood for Guitar Making – with Top-Class Acoustic Properties

The unique and innovative densification process is the key ingredient of Sonowood. This gives domestic wood characteristics that are measurably equivalent to those of tropical timber. The result? Sustainable square timber with outstanding hardness and density – the perfect materials for making high-quality guitars. Sonowood products enable luthiers to build guitars that raise the bar in terms of sustainability and provide top-class tonal characteristics.

Wood for Guitar Making with All the Characteristics of Tropical Timber – without Actually Containing Any.

We obtain woods like maple or beech from sustainably managed local forests and modify them to create sustainable wood for guitar making. The result is a groundbreaking innovation for luthiers: Sonowood. Thanks to its unique densification process, Sonowood measurably meets or exceeds the physical, mechanical and tonal properties of the tropical timber required for guitars. The extreme hardness and density of Sonowood help create guitars and electric guitars with outstanding acoustic characteristics when used as fretboards, bridges and head stocks.

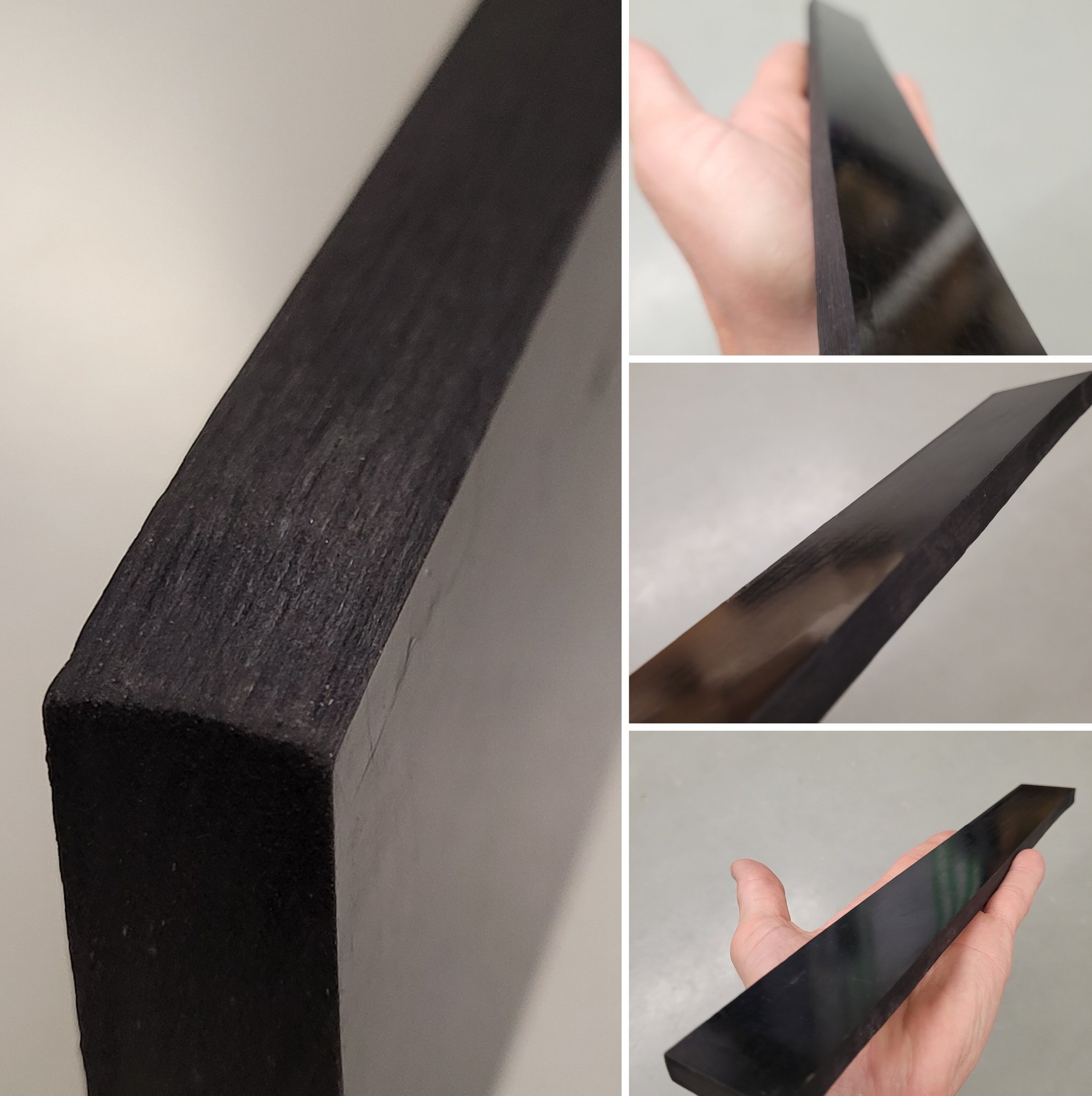

Sonowood Black Edition.

Sonowood Black Edition is available in shades ranging from dark brown to deep black. It functions as a genuine alternative to ebony – in terms of both its physical characteristics and appearance.

-

Spezifikationen Sonowood Black Edition

Type of wood: beech (Fagus sylvatica)

Color: very dark brown to black

Density: 1,200 – 1,400 kg/m³

Brinell hardness: > 80 N/mm²

Dimensional stability: height ~ 0.7%, width ~ 0.37% per % change in moisture content

Sound conduction speed: 4,200 – 5,400 m/s

Dynamic elasticity module: > 21,000 N/mm²

Sonowood Maple.

Sonowood Black Edition.

Sonowood Beech.

-

Specifications for Sonowood Maple/Flamed Maple

Type of wood: sycamore (Acer pseudoplatanus)

Color: mocha

Density: 1,200 – 1,400 kg/m³

Brinell hardness: > 80 N/mm²

Dimensional stability: differential swelling tolerance in % per % of moisture content change: height 0.7%, width 0.3%

Sound conduction speed: > 4,200 – 5,400 m/s

Damping (logarithmic decrement): ~ 0.053

Dynamic elasticity module: > 21,000 N/mm² -

Sonowood Black Edition

Type of wood: beech (Fagus sylvatica)

Color: very dark brown to black

Density: 1,200 – 1,400 kg/m³

Brinell hardness: > 80 N/mm²

Dimensional stability: differential swelling tolerance in % per % of moisture content change: height ~ 0.7%, width ~ 0.37%

Sound conduction speed: 4,200 – 5,400 m/s

Dynamic elasticity module: > 21,000 N/mm² -

Specifications for Sonowood Beech

Type of wood: beech (Fagus sylvatica)

Color: dark brown

Density: 1,200 – 1,400 kg/m³

Brinell hardness: > 80 N/mm²

Dimensional stability: differential swelling tolerance in % per % of moisture content change: height 0.7%, width 0.37%

Sound conduction speed: 4,200 – 5,400 m/s

Dynamic elasticity module: > 21,000 N/mm² -

Specifications for Ebony (Diospyros ebenum) as a Comparison

Density: 1,200 – 1,400 kg/m³

Brinell hardness: ~ 84 N/mm²

Sound conduction speed: ~ 4,500 m/s -

Standard Sizes for Sonowood Blanks

Fretboard: 540 x 65 x 10 mm

Bridge for acoustic and electric guitars: 200 x 50 x 20 mm

Other sizes available on request.

Interested in Sonowood?

If You Are an Instrument Maker:

Contact us.

We will be happy to discuss your individual requirements and answer any questions you have about Sonowood square timbers made from wood from sustainably managed local forests.

If You Are a Musician:

Contact one of our partners. Or ask your preferred luthier about Sonowood.

We have carefully selected our partners: these respected experts have extensive experience in crafting high-quality musical instruments – and they rely on Sonowood. They will be more than happy to help you with making or modifying your instrument.

We have established strong partnerships with recognized experts in instrument making, who use Sonowood square timbers to craft the parts of the instrument in close consultation with the artist, taking their requirements into account.

Discover Sonowood for Guitar Building on Our Partner's Website >

Sustainable Wood for Violin Making.

Sonowood is synonymous with exceptional hardness and density – the perfect prerequisites not only for guitars, but also for stringed instruments that meet the highest tonal requirements.

Read More About Sustainable Wood for Violin Making >